WAREHOUSE RACKING

Bo Racking works with state-of-the-art warehouse Storage Systems. We offer a wide range of products by top quality manufacturers and suppliers.

Bo Racking works with state-of-the-art warehouse Storage Systems. We offer a wide range of products by top quality manufacturers and suppliers.

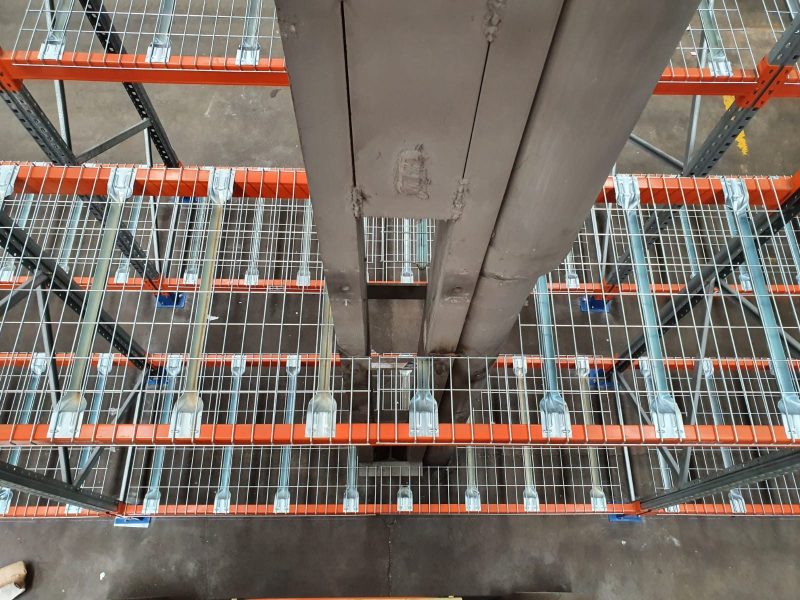

SELECTIVE PALLET RACKING

Because of its versatility and the range of custom options available, selective pallet racking is well suited to a variety of storage environments, ranging from small facilities to large warehouses.

Pros / Every pallet is easy accessible, compatible with nearly every forklift

Cons / Other storage solutions are able to create more pallet spaces than this solution

Forklift Requirements / No Special Requirements

Best fit and Use / Best suited for warehouses with a high intake and outgoing of pallets

Our pallet racking is certified, not just complies, to Australia’s most recent steel and safety standard AS4084-2012. This can be very important to your business for safety and insurance purposes.

DOUBLE DEEP PALLET RACKING

Double Deep Pallet Racking is designed to maximise storage space in your warehouse or storage facility by removing the need for aisles, it is ideal for slow moving stock or long term storage.

Pros / Maximizes the storage space by removing the need of aisles

Cons / Access of pallets stored in the 2nd row can take some extra time

Forklift Requirements / A double deep reach forklift is mandatory

Best fit and Use / Best suited for warehouses with slow moving stock or long term storage

CANTILEVER RACKING

Cantilever racking is an essential solution for loads that must have no ‘face’ obstruction, so that hefty and odd sized products can be easily stored and accessed. This type of cantilever racking allows you to use your warehouse space more efficiently, ¬ you’ll never need to clutter floor areas with annoying columns obstructing your storage space again.

You can easily fit these systems within your facility by adjusting the height, ensuring that the most amount of vertical storage space is exploited. The open rows allow secure load support and also easy access, safety, flexibility and selective ability are all maintained to a gold standard.

Pros / Allows to store hefty and odd sized products in an easy manner and product is easy accessible at all time

Arms are easy to adjust in height to allow a customization suited to your product

Cons / Not suited for standard size pallets. Only for oversized pallets and other long materials

Forklift Requirements / No Special Requirements

Best fit and Use / Best suited for warehouses which stock store long, bulky, and oversized loads like timber, pipes, trusses and plywood

DRIVE IN RACKING

Drive in Pallet Racking is ideal for stocking many products. It can reduce overall Sq. footage requirements by 35% or more compared to standard selective racking. It is widely used in cold storage and food industries.If you are storing large volumes of goods, we offer a Drive In Racking system that can free up existing floor space. Our Drive In Racking system creates efficiency by decreasing aisle loading & unloading times, yet allowing greater access in comparison to block stacking.

Pros / Maximizes the storage space by removing the need of aisles, Compatible with most forklifts

Cons / Access of pallets stored in the back is restricted

Forklift Requirements / No Special Requirements

Best fit and Use / Best suited for warehouses with slow moving stock or long term storage

NARROW-AISLE RACKING

Narrow Aisle Racking provides 100% pallet accessibility whilst increasing storage space within your warehouse. Narrow Aisle Racking is ideal for all types of pallet storage, and can be built to accommodate different sized pallets on each level.

Pros / Increases the storage space while the accessibility of each pallet is not affected

Cons / Narrower aisles can slow down the process and needs skilled forklift operators

Forklift Requirements / Narrow Aisle reach forklift or order picker is mandatory

Best fit and Use / Best suited for warehouses with a high intake and outgoing of pallets

PALLET FLOW/LIVE STORAGE

Pallet flow is the most common FIFO( 1st in-1st out)system.Pallet flow uses roll tracks to send pallets from on load end to off load end with forklift only dropping off or picking up single pallets , with no need to “enter” the rack structure saving time and also constant repairs of internal framing when accidentally damaged.

Pros / Maximize the storage space by removing the need of aisles, Compatible with nearly every forklift

Cons / Accessibility of pallets is restricted

Forklift Requirements / No Special Requirements

Best fit and Use / Best suited for warehouses with the FIFO System (First in – First out)

WAREHOUSE RACKING ACCESORIES

Bo Racking uses a wide range of racking accessories. If you don’t see what you’re looking for here contact us and we will find it. We are committed to keeping your pallet racking safe and up to date.

• Rollover Gate for Mezzanine

• Heavy Duty Castor (With Brake)

• End Row Barriers

• Post Protectors

• Timber Support Bars

• Safety Clips

• Collapsible Stillage

• Wire Mesh Deck

To apply for a job at Bo Racking please send a resume together with your cover letter to.